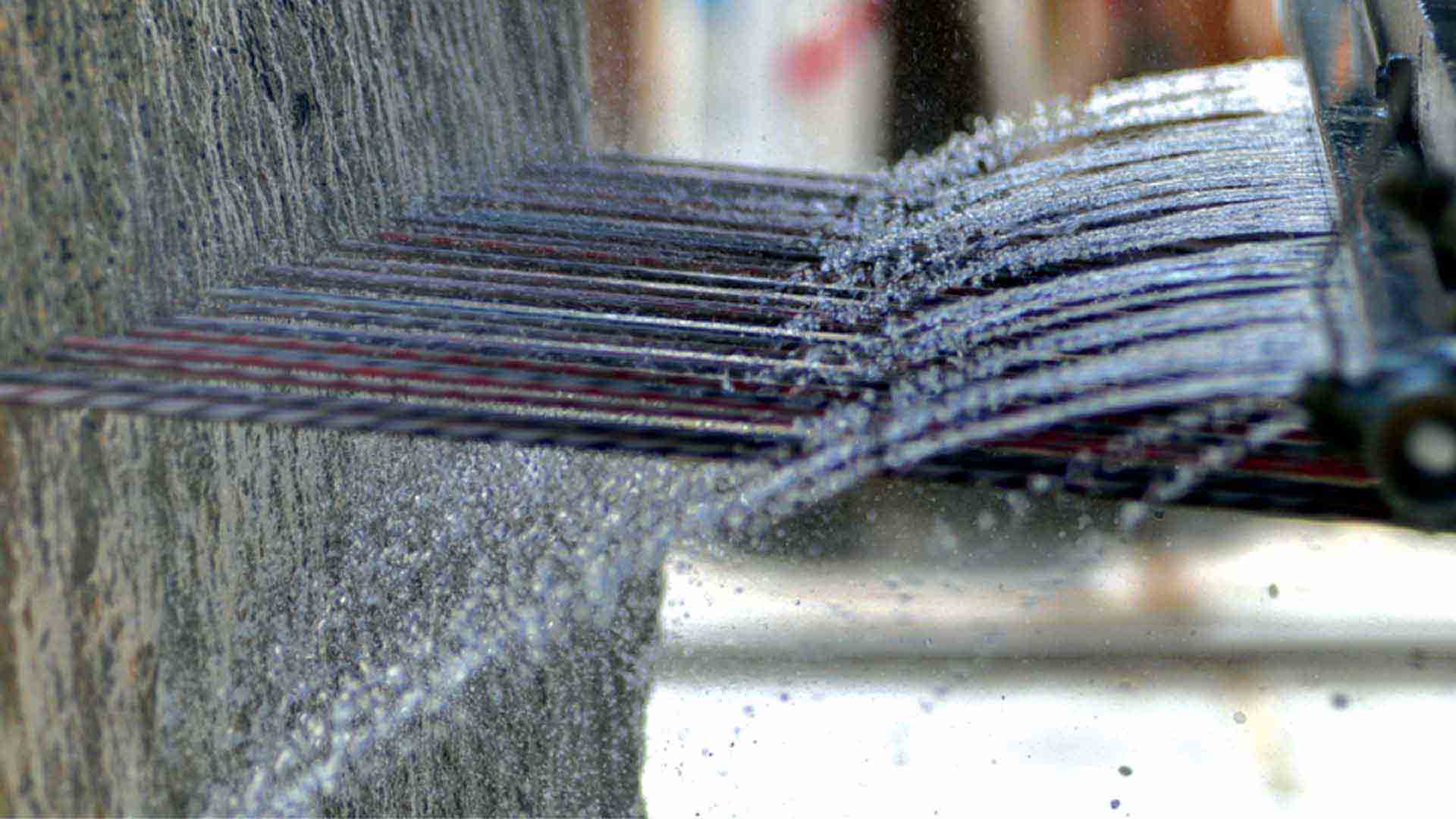

Diamond Wire Saws for Granite Quarry

At present, the diamond wire saw have already used more and more for quarries. They have more advantage than traditional quarry operation. They are high efficiency and high output and lower waste of quarry resource. They can be used for great area cutting .The block is regular, without internal injury, It is low-noisy, no-dust and safe operation.

|

Diameter

(mm) |

Fitting |

Beads/Meter |

Sawing speed

(©O/h) |

Lifetime (©O/m) |

Liner speed (m/s) |

|

¦µ11.5

|

Rubber / Plastic |

40 |

4-6 |

15-25 |

25-30 |

|

Rubber / Plastic |

40 |

2-5 |

8-15 |

22-26 |

|

Rubber / Plastic |

40 |

1-2.5 |

4-9 |

18-23 |

|

¦µ11

|

Rubber / Plastic |

40 |

5-7 |

15-20 |

25-30 |

|

Rubber / Plastic |

40 |

3-5 |

8-13 |

22-26 |

|

Rubber / Plastic |

40 |

1-2.5 |

4-8 |

18-23 |

|

¦µ10.5

|

Rubber / Plastic |

40 |

5-7 |

15-20 |

25-30 |

|

Rubber / Plastic |

40 |

3-5 |

8-13 |

22-26 |

|

Rubber / Plastic |

40 |

2-3 |

4-8 |

18-23 |

Different Granite type we can provide different bone hardness (HRB 95-105)

Different Granite type we can provide different length of segmented part of the beads.

We have developed a special rubber and special vulcanization process. It increased resistance to abrasion which comes from the harshest working conditions.

Diamond Wire Saws for Granite Profiling

The advantage of the diamond wires for profiling are stable cutting, high performance, smooth cutting face, and accurate of processing ect.

|

Diameter

(mm) |

Fitting |

Beads/M |

Material type |

Sawing speed

(mm/min) |

Lifetime

(©O/m) |

Liner speed

(m/s) |

|

¦µ10.5

¦µ8.8

¦µ8.5

¦µ8.2 |

Plastic |

37 |

Class 1-2

Class 3- 4

Class 5 |

10-15

5-10

3-6 |

9-13

7-11

5-8 |

26-30

24-28

20-24 |

Note: The sawing speed is calculated by sawing depth (mm) per minute.

1. The rotation of the wire should be regularly checked

2. The beads wear profile should be regularly inspected

3. The connections should be changed whenever excessively high wear of the adjacent beads is noted

4. The cable tension is set to 250-300kg(4-5mmdiameter cable)

5. Adjust the liner speed of the wire to the material being sawn:

Granite class 1¡ª2: 25¡ª30m/s

Granite class 3¡ª4: 22¡ª26m/s

Granite class 5: 20¡ª24m/s

Marble: 30¡ª35m/s

Abrasive stone: 30¡ª35m/s

6. During the sharpening of a new wire ,the liner speed must be reduced by 2-3m/s

7. Water spraying between 15-25L/min

Diamond Wire Saws for Granite squaring and cutting

1£®The wire allows significantly greater sawing heights than large discs.

2£®Thinner cutting width, and more precise .

3£®By virtue of its reliability, adjust the cutting techniques according to different stone material.

4£®Noise nuisance generated by diamond wire saw is significantly less than produced by other sawing techniques.

|

Diameter

(mm) |

Fitting |

Beads/M |

Material type |

Sawing speed

(m2/h) |

Lifetime

(m2/m) |

Liner speed

£¨m/s£© |

|

¦µ11 |

Plastic |

37 |

Class 1-2

Class 3-4

Class 5 |

1.5-2.5

1-1.5

0.6-1.0 |

12-20

8-13

4-8 |

26-30

24-28

20-24 |

|

¦µ10.5 |

|

¦µ10 |

|